Law Suit

Research and Development

We develop customized solutions, focusing on technology, increased product shelf life and improved processes. The constant search for new formulas, structures and finishes adds value to the final product, reduces costs and minimizes environmental impacts.

Pre Print

Prepress has modern software tools on the Mac platform for preparing files, like Art Pro, Nexus, Illustrator e Photoshop. Esko digital copying equipment, digital proofs and substrate proofs ensure accuracy, speed and confidence in the tests.

Flexography and gravure cylinders are produced in-house, ensuring agility and quality.

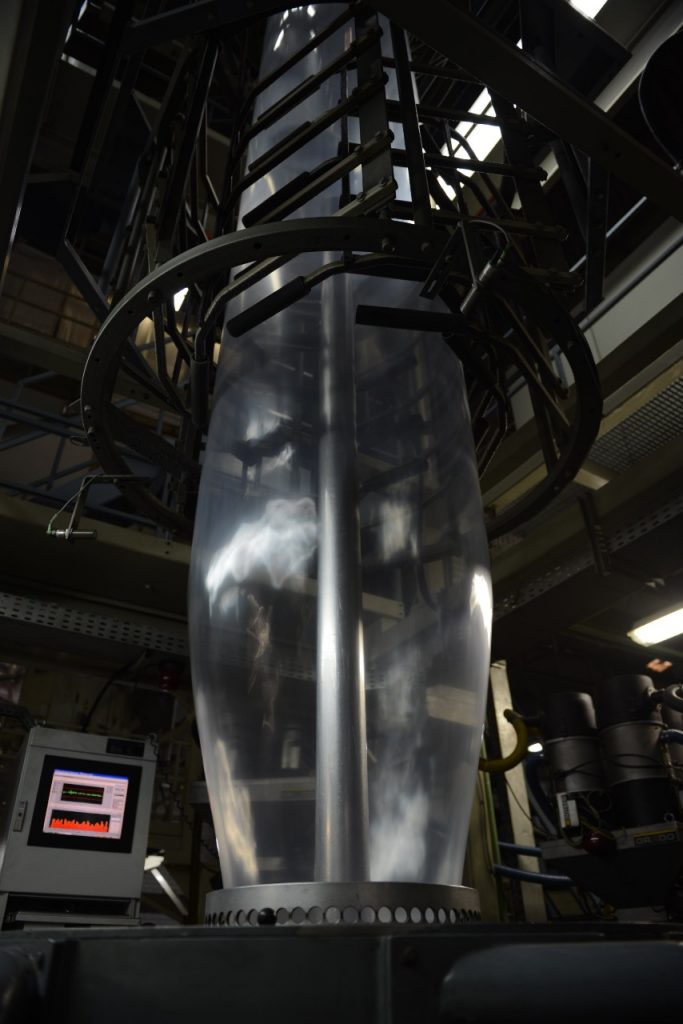

Extrusion

Extruder machines 5 layers provide mechanical resistance and barrier to the film, which guarantees good airtightness, sealability and machinability.

Incoplast has 2 printing processes. Flexography and rotogravure. Rotogravure is characterized by speed, high definition images and color fidelity. In this type of printing, copper cylinders engraved with small “alveoli” are used. The process is suitable for long, repetitive runs. Flexography uses clichés, large “rubber stamps” that transfer the ink to the substrate. Gearless printers ensure greater accuracy, definition and speed of adjustment. With the technological advances in the prepress and printing area, flexography has been gaining market due to the improvement in quality. Incoplast flexography is confused with rotogravure, such print quality.

Lamination

Lamination materials with solvent and solventless, adds barriers, resistance, adds value and protection to the final product.

Finishing

A wide variety of finishes to enhance the product: stand-up pouch, wickter, tamper-proof seal systems, zippers, easy open, square background, side accordion, concertina background, four welds, valves, film handles and reels.